Polyester Nanofiber

Life Evolves with Fibers

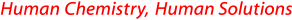

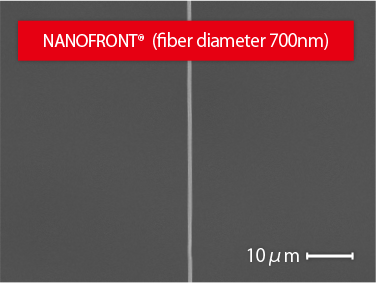

Teijin Frontier has been working on the development of nanofiber from the start of the 21st century. We have spent time and efforts on mass-production technology development, and searched for new areas where the nanofiber can be introduced. Then in 2008, we were first in the world to successfully begin commercial production of superior-strength filament polyester nanofiber "NANOFRONT®", featuring the innovative characteristic of uniform 700-nanometer diameter.

NANOFRONT® has an ultra-fine structure, slip-resistance, is soft to the touch, great for cleaning, and very translucent. With these features, NANOFRONT® can be used in a wide range of applications, from clothing to various industrial products.

Features of Various Technologies and Products

1. Polymer designing and precise composite polymer fiber technology

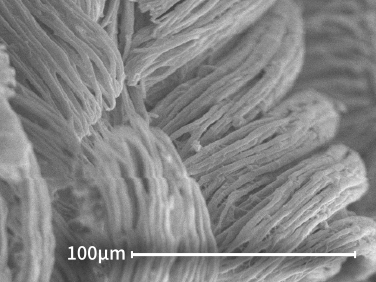

To make even finer and stronger fiber, we worked to improve "sea-island" composite fiber technology. Our newly developed spinneret provides several hundreds to a thousand "islands" inside a fiber, many more than microfibers currently on the market. This sea-island composite fiber is stretched under high tension, promoting fiber structure formation. Not only that, we also designed a polyester for the "sea" composite that has a hydrolysis rate more than 1000 times faster than the polyester for the "island" composite. This makes it possible to dissolve and fully remove the polyester using a more environmentally friendly aqueous-base solvent.

Using the established technologies, we are stepping forward in developing the nanofibers from polymers other than regular polyester (polyethylene terephthalate) and nanofibers that are finer than 700 nm.

2. Processing technology and structural design technology

We created processing technology based on the aforementioned polymer design and precise composite fiber technology. The sea and island components are dissolved and separated evenly using aqueous solvents. We also created structure design technologies for our unique fiber processing technology, textile, and non-woven fabric.

Compositing a large number of nanofibers into high density, two or three-dimensional structures generates nano-size effects giving it a large surface area, enhanced adsorption, added softness, and "separation" effects. Then, we utilized our product development technologies to use those nano-size effects, to make new products. This helped us create various new functional products that are less slippery, soft to the touch, great for cleaning, and very translucent.

Fiber technology

3. Functional verification technology of the developed product

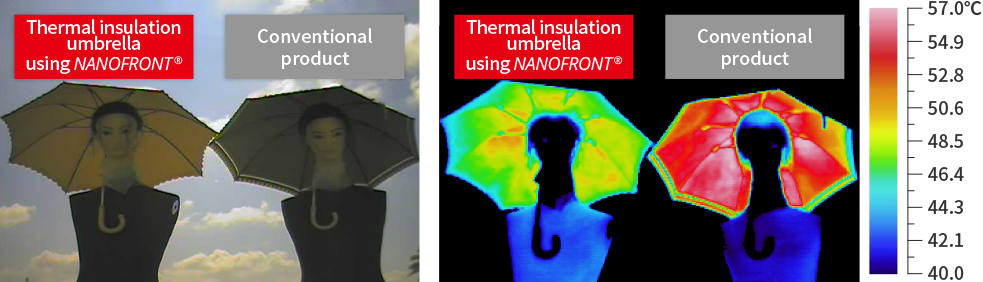

Example products using the advantages of "nano-size effects" are ergonomics based motion assistance products with higher grip performance, and a muscle vibration inhibitor; cosmetics and skin care products (household goods) that are adhesive and supple; thermal insulation products such as an umbrella that reflects the near-infrared light effectively using the large surface area and the super-fine structure of the nano-fibers; polishing cloth and high-function filter for precise and high-performance industrial materials. When we commercialize new products, we also work on developing new evaluation technologies based on consumer research to introduce new values to the world.

Examples of NANOFRONT® products

1. Golf gloves - No slippage

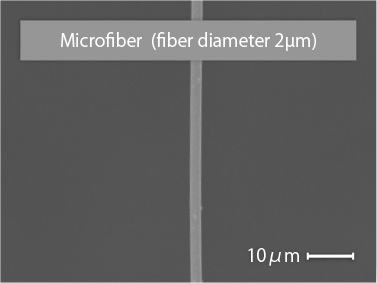

The nano-size fiber increases the contact area between the fabric and the grip, and between the fabric and the hand. This generates greater frictional resistance and exhibits a greater gripping power to prevent slippage and mistakes. The surface structure of the NANOFRONT® mimics the structures of Japanese gecko and leaf beetle's legs.

Their strong grip shows that the structure provides large frictional resistance (biomimetics). The super fine fabric provides additional unique features that other commercial glove materials don't have. The glove is soft to the touch providing a unique fit feeling - like an extra layer of skin. The frictional resistance increases when it gets wet from sweat or rain.

NANOFRONT® fabric was used for golf gloves in 2009. Since then, the fabric is known as the third material compared to the natural and synthetic leathers, and used by many large golf glove manufacturers.

This slip-resistant effect is used in not only gloves for different sports and work operations, but for socks and supporting gears. It can also be used for products for our daily lives.

2. Umbrella - Translucency

Since the diameter of the fiber is similar to the wavelength of the light (several hundreds to a few thousand nm), its surface area is several tens of times larger than regular fabric and the space between the fibers has a super fine, nano-level structure. Spreading the NANOFRONT® uniformly in layers made it possible to effectively reflect the near-infrared light (heat rays) and resulted in the production of high thermal insulation umbrellas. The conventional technologies apply thermal-insulation reagents on the surface of finished-products. However, as thermal insulation effects of the NANOFRONT® come from its own structure, the effects will not be lost over its lifetime.

Comparison of temperature above head

3. High-performance filter - Using the separation effect

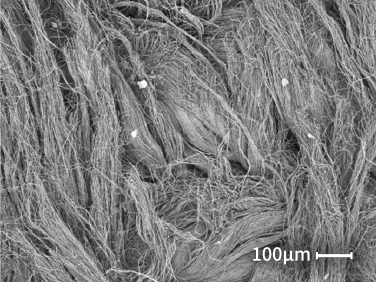

The filters used for clean rooms require energy-saving and high-performance while also maintaining low-pressure-loss, a long-operating life, and high collection efficiency. Previous studies showed combinations of fibers with various diameters, including nanofibers, is the key to fulfill these contradicting needs.

However, commonly used material for fitters is 300 nm glass fibers, which is not environment friendly. On the other hand, NANOFRONT® is safe to burn, and thus is considered more environmentally conscious.

NANOFRONT® is expected to fill the gap between the filter and the membrane ? which no other material has been able to do so far. So we are putting our efforts into developing liquid processing filters, air filters, and medical device filters with a large degree of freedom in design.

We will keep trying our best to be the frontier of the technology, finding new ways and areas where our product will be useful, by listening and responding to various customer needs and expanding our product variations.