Resource Recycling

Metrics and Targets

The Group's target (KPI)

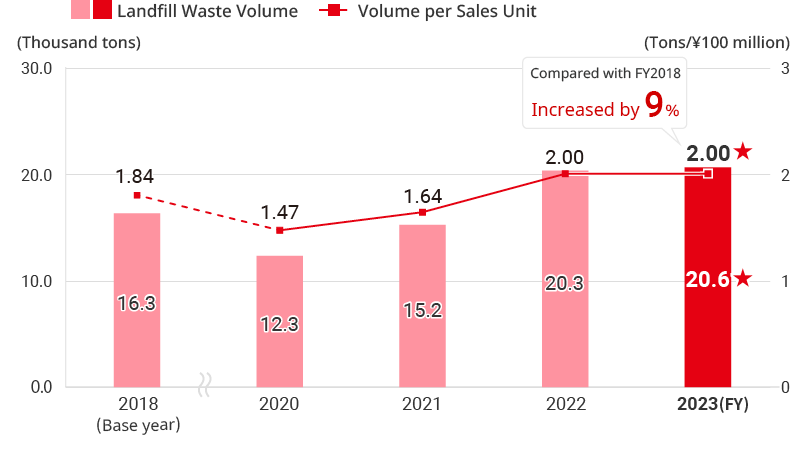

FY2030: 20% improvement in landfill waste volume per sales unit (compared with FY2018)

In FY2024, our landfill waste volume was 2.3 thousand tons , and the volume per sales unit was 0.27 tons/100 million yen

, and the volume per sales unit was 0.27 tons/100 million yen .

.

Trends in landfill waste volume and volume per sales unit

- *Teijin Automotive Technologies NA Holdings Corp. (hereinafter, "TAT-NA"), a consolidated subsidiary in the materials segment that operates the automotive composites business in North America, has been excluded from the scope of aggregation from FY2024 due to it being a discontinued operation. Past figures include TAT-NA, while figures for FY2024 exclude TAT-NA. The figures in parentheses are reference values that include TAT-NA and are not subject to third-party assurance.

- *Per sales units are calculated using consolidated net sales as the denominator. Note that for FY2024, the denominator in the calculation is the amount obtained after deducting the net sales of companies outside the boundary from the consolidated net sales.

- *Landfill waste volume is calculated based on the amount of waste disposed of directly in landfills.

Initiatives

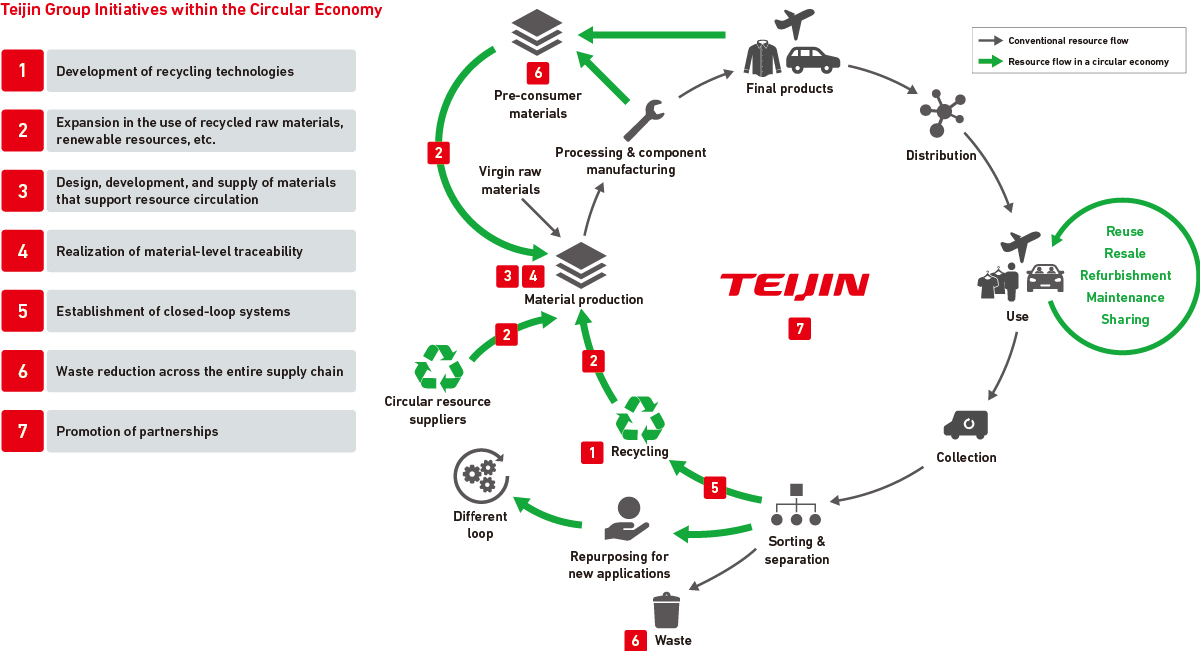

Toward Realizing a Circular Economy

The Teijin Group is promoting initiatives for the achievement of a circular economy. The achievement of a circular economy requires using resources efficiently for as long as possible. By maintaining the value of resources and utilizing them effectively, it is necessary to reduce environmental impact and minimize waste and the release of hazardous substances throughout the entire life cycle of products and services. Working with a broad network of partners, the Teijin Group promotes initiatives such as the seven listed below across different stages of the value chain.

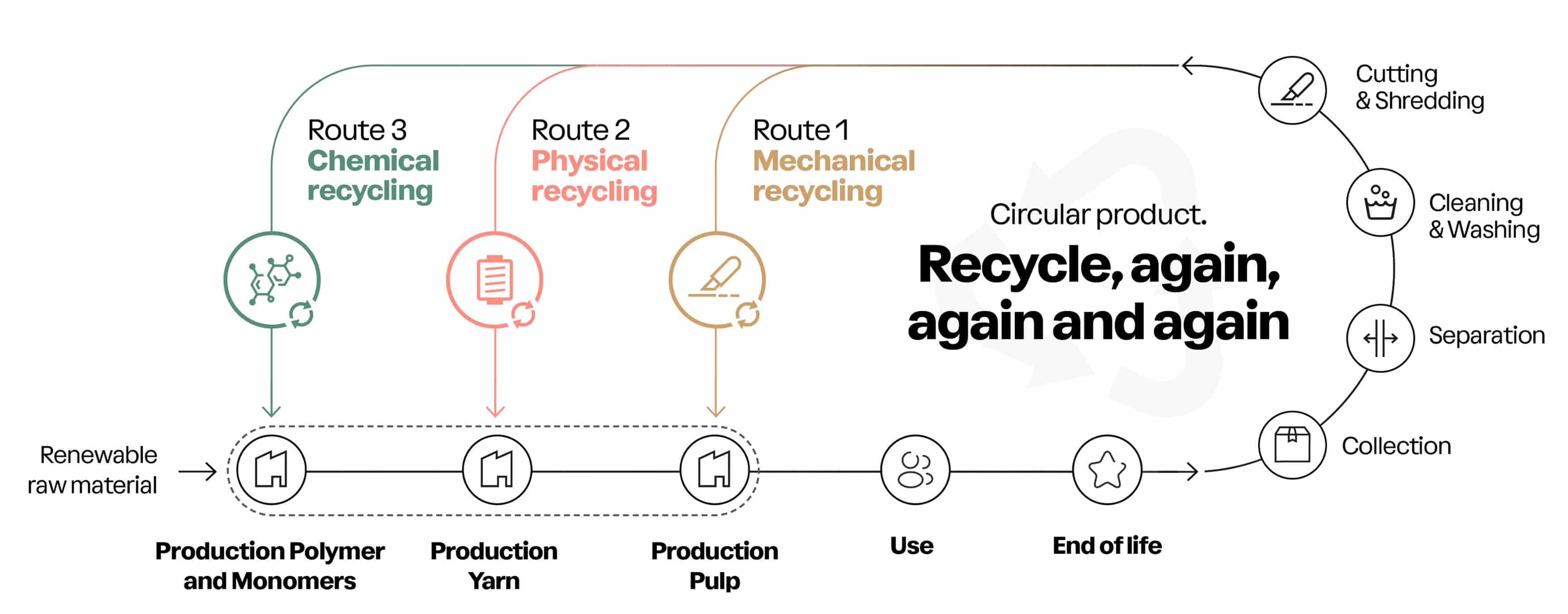

Aramid Fiber Circular Production Process

Teijin Aramid B.V. is working toward a circular economy. For more than 20 years, Teijin Aramid has had a successful record of mechanically recycling end-of-life products to Twaron pulp. Teijin Aramid plans to gradually move forward with the circular production process using various innovative technologies and sources of pre- and post-consumer waste. Teijin Aramid has been making progress on developing a physical recycling technology for fiber-to-fiber recycling. The first industrial-scale production run was achieved in April 2023, followed by a second run in April 2024. Teijin Aramid is also working on the development of chemical recycling technology for aramid fibers; this is a longer-term development. Next to the recycling technologies, Teijin Aramid is working on procuring sustainable raw materials from its suppliers. Teijin will comply with future regulations while meeting customer demands.

Release of DPP proof-of-concept Compliant with Europe's ESPR

In November 2024, we invested in Circularise B.V., a Dutch IT company, to advance the development of products compliant with the EU Ecodesign for Sustainable Products Regulation (ESPR). Using Circularise's system, we have released proof-of-concept results for selected aramid and carbon fiber products featuring Digital Product Passport (DPP)*.

- *Digital Product Passport (DPP): a digital certificate that comprehensively records when, where, and with what materials a product is manufactured, used, and disposed of throughout its lifecycle.

Aramid fiber (DPP for the recycled product)

Example of traceability for pulp recycled from end-of-life aramid-fiber products

Carbon fiber (DPP for the tire lever)

Example of traceability for a tire lever hypothetically manufactured with our carbon fiber for installing and removing bicycle tires